Brand

Overview

Description

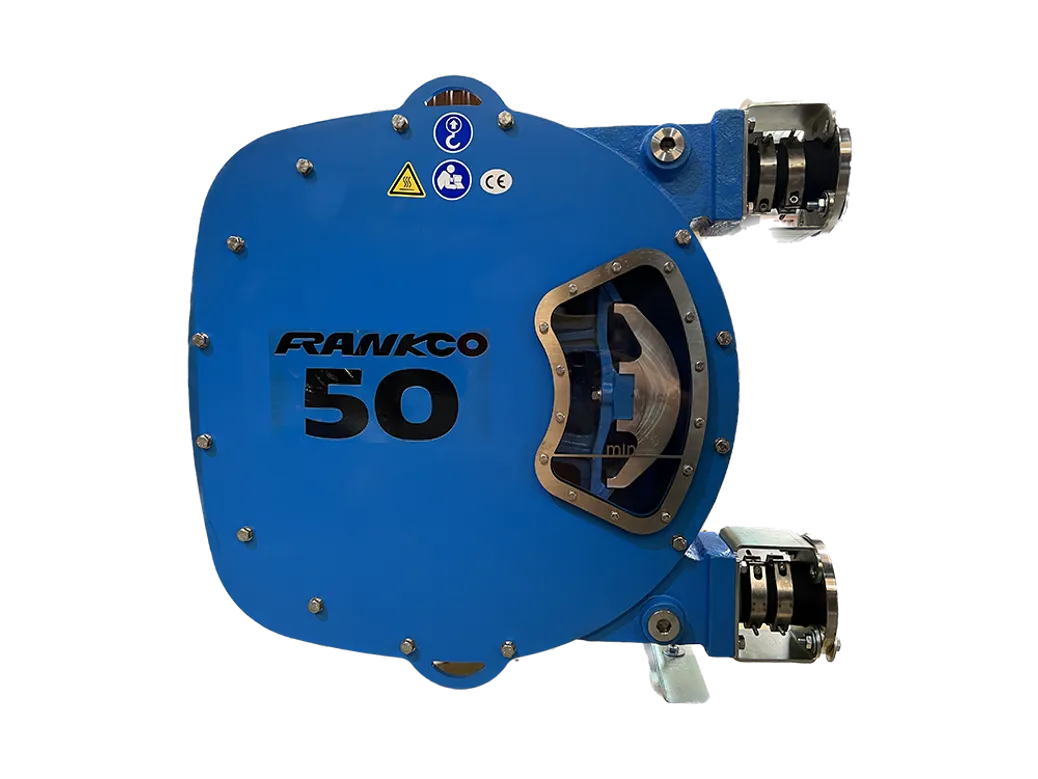

Peristaltic Pumps for FRANKCO Hose Pumps: Engineered for Durability and Performance

Built-In Bearing System : All FRANKCO pumps feature a built-in bearing system that absorbs shaft loads during hose compression. This design relieves stress on the gearbox, extending its lifespan and ensuring consistent performance.

Seal-less, valve-less design Affordable, accurate and reliable. Engineered for a more competitive price/performance. Reduced cost of ownership compared to other PD pumps

Extended Component Life : Every material and design element is chosen for its strength and longevity. The only part that naturally wears over time is the hose, contributing to an overall longer pump life.

Easy Maintenance : Despite their durability, The pump’s innovative design allows for quick disassembly when the hose needs changing. Shorter maintenance times compared to other pump types.

Proprietary Hose Manufacturing Process : Each component of the hose-the inner layer, textile reinforcement, and outer layer—is meticulously crafted to outperform other hoses. Our advanced manufacturing process combines the best techniques from across the industry.

Uncompromised Quality Standards : The hose, being the primary wear component, is a key factor in maximizing performance and efficiency. FRANKCO hoses are produced using top-quality materials and undergo rigorous quality control to ensure exceptional performance and durability.

Minimized Downtime : The long-lasting hose not only reduces replacement costs but also minimizes pump downtime. With fewer interruptions to replace the hose, FRANKCO pumps keep your operations running smoothly and efficiently.

Technical specifications

| Technical specifications | |

| FLOW RATE RANGE | 5 to 66,000 l/h |

| MAXIMUM PRESSURE | 16 bar |

| INNER DIAMETER | 10 to 125 mm |

| MATERIAL OF CONNECTIONS | ABS, Stainless steel, Titanium |

| MAX. TEMPERATURE | 80ºC |

| MATERIAL OF HOSE | NR, NBR, EPDM, CSM, F-NR, F-NBR |

Models by Series

Related Products

Ready to working with us?

Please fill in the following form. You will be contacted as soon as possible.